Core Capabilities

Medical Surveillance

Confirm that employees subjected to critical stressors stay healthy.

Medical Surveillance

Confirm that employees subjected to critical stressors stay healthy.

7 Simple Steps to Improve Your Industrial Hygiene Program

GUIDE

Download our guide to learn the key strategies for easily and efficiently coordinating and managing all the moving parts of your Industrial Hygiene program.

Benefits of VelocityEHS

Industrial Hygiene Software

Simple Solution

- Centralize information & activity in a single system

- Pre-built templates & auto-populated fields

- Access full chemical and OEL database

- Consult the list of stressors, laboratory sampling & analytical guides

Sustainable System

- Auto-assign personnel to Similar Exposure Groups (SEGs)

- Manage sampling plans & medical surveillance programs

- Track SEGs & flag for qualitative exposure assessments (QEAs)

- Launch & deliver large scale online office ergonomics process

Program Management

- Grant labs & consultants secure access to upload data directly

- Perform in-depth statistical analysis of sample data

- Show value of IH to c-suite with real-time reports & risk matrices

- Document decisions & take control of chain-of-custody

What our customers say…

“At HIH, we’re all about making things easy for our clients, removing barriers and doing what it takes to help them get the job done… I could see that VelocityEHS Industrial Hygiene Software was very user friendly, offered greater flexibility of data, and could help us eliminate many complex manual data management tasks. It’s just perfect, I think.”

The EHS Software Revolution Has Begun

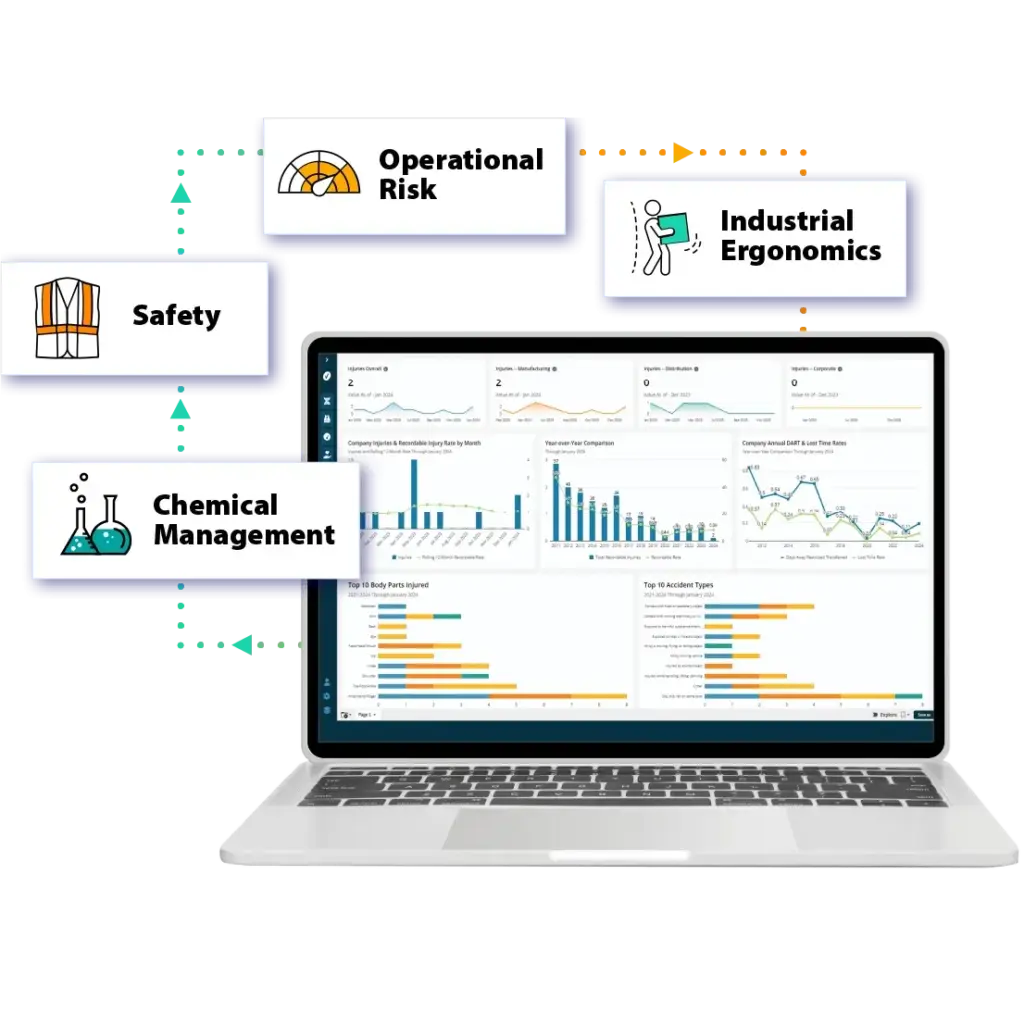

Introducing the VelocityEHS

Accelerate® Platform

The industry’s first truly integrated EHS platform on the market, streamlining Velocity’s Safety, Ergonomics, Chemical Management, and Operational Risk capabilities into one seamless solution.

Activations are underway. Secure your spot today!

Prevent Harm

Send workers home safe with solutions that cover a range of risks.

Drive Engagement

Reduce training time and simplify complex tasks with in-app guides.

Save Time

Free managers from tedious administration with centralized controls.

Be Predictive

Anticipate & address risk with real-time data you can trust.

Increase Visibility

Unite every level of your organization via shared dashboards & reports.

Embrace Innovation

Harness machine learning + AI & automation to deliver expert-level results, faster.

Stay Ahead of the Curve

We’re continually investing in breakthrough technology and best practices, creating engaging content, and supporting our customers’ efforts to use their EHS/ESG programs to drive sustainable change.

Job Safety Analysis (JSA): The Essential Occupational Health and Safety Management Tool

Operational Risk

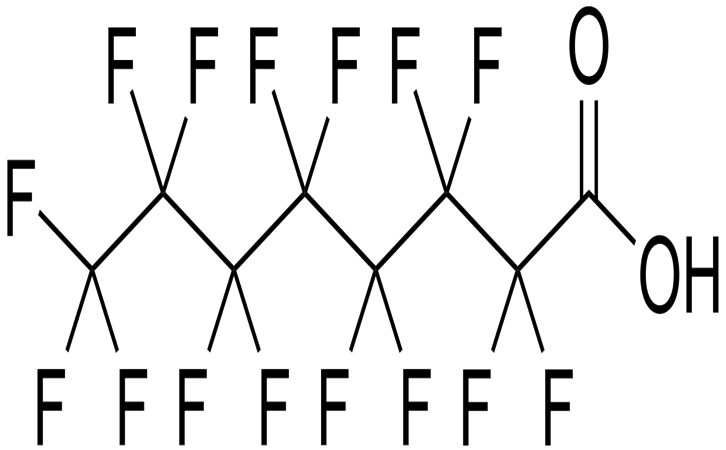

Managing PFAS: Here’s What You Need to Know

Safety

What are PFAS, why are they important, and what do you most need to know about them?

Key Insights from OSHA 2024 Injury and Illness Data

Safety

OSHA’s 2024 data shows injury rates returning to pre-pandemic levels, with healthcare leading and respiratory issues on the rise.

Schedule a Demo Today

You’re not just buying software or services—you’re investing in a partnership that empowers your team to proactively solve problems and move boldly into the future.