Welcome to the fifth and final installment of our series, “Introduction to Hazardous Waste Management,” in which we’ll discuss the importance of waste reporting and waste minimization toward maintaining compliance with hazardous waste regulations and pursuing EHS/ESG maturity. In case you missed the previous installments, check out Part One to find out how to determine if your waste is hazardous, Part Two for a primer on how to determine your generator status and associated compliance obligations, Part Three for an overview of managing hazardous wastes on-site, and Part Four for a discussion of generator pre-transport and manifest requirements.

If you’re all caught up, let’s dive right into the fundamentals of hazardous waste reporting.

Managing Your Waste Reporting

Reporting will be one of your most important tasks, because so much of compliance and waste minimization depends on getting it right. You’ll need to focus on both regulatory-driven reporting, as well as internal reporting on the status and progress of your organization’s waste management practices.

Regulatory-Driven Hazardous Waste Reporting

In a previous installment of this blog series, we discussed the different regulatory requirements for each of the three classes of hazardous waste generators. The Resource Conservation and Recovery Act (RCRA) requires large quantity generators (LQGs) to submit a biennial hazardous waste report (HWR) summarizing information about off-site shipments of hazardous waste during the previous calendar year. Federal EPA does not require small quantity generators (SQGs) to complete and submit biennial reports, but many states do. If your facility is an SQG, be sure to check the requirements in the state(s) where you operate.

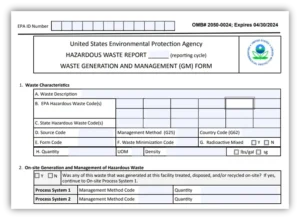

Information in the HWR includes:

- Facility’s EPA ID Number;

- Facility’s name and address;

- Quantity and nature of hazardous waste generated, including EPA waste codes;

- Whether the generator treated, disposed or recycled any hazardous waste on-site, and if so, the management method codes used;

- Whether the generator sent the hazardous waste offsite for recycling, treatment, storage, or disposal; and

- The EPA ID numbers of treatment, storage and disposal facilities (TSDF) that received your hazardous wastes

The image below shows a section of the HWR.

Of course, the HWR is only one report a hazardous waste generator may potentially need to submit. Other reports include:

- Exception report: RCRA requires LQGs to submit an Exception Report to the EPA Regional Administrator for the Region in which the generator is located if the Administrator has not received a copy of the manifest with the handwritten signature of the owner or operator of the designated facility within 45 days of the date the initial transporter accepted the waste. SQGs who do not receive a final, signed copy of the manifest back within 60 days must also file an exception report. State requirements may be more stringent than these federal requirements, so don’t forget to check your state EPA authority to ensure you’re aware of your obligations. The Exception Report must include:

- Toxic Release Inventory (TRI) reporting: The regulatory obligation to complete and submit an annual TRI report (also commonly referred to as a “Form R” report) comes from chemical management regulations under the Emergency Planning and Community Right-to-Know Act (EPCRA) rather than RCRA hazardous waste regulations. Many generators of hazardous waste would also have TRI reporting responsibilities, and if so, would need to complete the report each year by July 1 for the previous calendar year and include data such as amounts of wastes shipped offsite, amounts of wastes treated on-site (if any), and names of TSDFs that received waste shipments.

As we discussed in another previous installment of this series, EPA issued a proposed rule earlier this year to revise aspects of the hazardous waste manifest form, as well as to seek stakeholder input on whether to integrate the electronic manifesting (e-Manifest) system with various hazardous waste reporting requirements and how such integration might work. As of this writing, we have yet to see what type of reporting integration EPA will pursue once they sort through public comments, analyze feedback, and issue a final rulemaking.

Internal Waste Reporting Practices

While regulatory-driven reporting is important, pursuit of waste management best practices means going beyond the regulations. This is especially true if you’re seeking alignment with voluntary environmental management standards like ISO 14001 or ESG reporting frameworks like SASB or GRI. You need deeper analysis of the wastes you generate, whether hazardous or nonhazardous, where you’re generating them, where you’re shipping them, and how much it’s costing you. Most of all, you need easy ways of sharing this information with your team members so you can establish the common understanding of challenges and successes needed to drive better performance.

Modern Environmental Compliance software can help here, by facilitating monthly reporting on waste by waste type and quantity, monitoring of waste shipment transit times and documentation of contractor communications. You also can manage waste costs and rebates from a central location, and analyze costs by time, type of waste, or vendor.

Developing Waste Minimization Programs

EPA defines waste minimization as “the reduction, to the extent feasible, in the amount of hazardous waste generated prior to any treatment, storage, or disposal of the waste.” In the instructions for the HWR, EPA further explains that minimization includes any source reduction or recycling activity undertaken by a generator that results in the reduction of total volume or quantity of hazardous waste, the reduction of toxicity of hazardous waste or both, “as long as the reduction is consistent with the goal of minimizing present and future threats to human health and the environment.”

Waste minimization strategies include:

- Source reduction: This method, also known as pollution prevention (P2), involves reducing or eliminating the generation of waste at the source, usually by reducing the amounts of chemicals that become hazardous wastes through production processes. Examples of source reduction include replacement of lead-containing alloys in solders, and replacement of lower flash point cleaning solvents with solvents that have flash points above 140 degrees Fahrenheit, which would not be RCRA-defined ignitable wastes after use.

- Recycling. Business leaders can use recycling when direct source reduction strategies like replacement of formulation components is not feasible. “Recycling” is a broad term that encompasses the reuse of materials in either original or altered forms rather than disposing of them as wastes. For example, if you have used solvent, you may be able to reuse it (potentially even more than once) rather than simply discarding it. This reuse reduces the amount of waste solvent generated at any one time.

- Recovery. There are a couple of key types of recovery. In materials recovery, we take a used material that we can no longer directly reuse and process it in some way to generate a usable product once again. In energy recovery, we either directly use a hazardous waste as a source of energy or treat it to produce a usable energy source.

The latter two categories come with important additional considerations. First, EPA has created certain exclusions intended to encourage recycling of hazardous waste and provides a useful summary at its page “Regulatory Exclusions and Alternative Standards for the Recycling of Materials, Solid Wastes and Hazardous Wastes.” Also, keep in mind that if you choose to do energy recovery on-site you’ll have additional regulatory obligations. For example, operators of units burning hazardous wastes for energy recovery would need to comply with operating standards for units burning hazardous wastes for energy recovery in 40 CFR part 266 subpart H and would need to meet Maximum Available Control Technology (MACT) air emissions standards.

Waste minimization is not always simply a “nice-to-have,” because it can sometimes be a regulatory requirement. Federal RCRA regulations require all large quantity generators (LQGs) to have a formal waste minimization program in place, while requiring small quantity generators (SQGs) to make a “good faith effort” to reduce hazardous waste generation. There’s no corresponding requirement for very small quantity generators (VSQGs), but it’s also important to remember that having waste minimization programs in place is a often a necessary strategy for staying a VSQG.

This is an important example of how waste minimization can be a valuable strategy for maintaining stability and predictability of our regulatory compliance obligations. A secondary benefit is the reduction of costs associated with management and shipping of hazardous wastes. These benefits explain the growing attractiveness of the “exiting RCRA” concept— that is, reducing hazardous waste generation to levels where RCRA regulatory compliance is no longer a significant burden. Companies that find methods to reduce the volume or toxicity of hazardous waste can significantly reduce their regulatory burdens, better protect their workers and the environment, and improve ESG and sustainability.

Still, company leaders need to understand the difference between recycling and “sham recycling.” EPA recognized the importance of this distinction enough to create a page detailing the differences, and laying out the characteristics of legitimate recycling, which include:

- Legitimate recycling involves a hazardous secondary material that provides a useful contribution to the recycling process or to a product or intermediate of the recycling process;

- The recycling process must produce a valuable product or intermediate;

- The generator and recycler must manage the hazardous secondary material as a valuable commodity while it is under their control; and

- The product of the recycling process is analogous to a legitimate product or intermediate.

Sham recycling deviates from these criteria in several ways and may include situations in which the “recycled” secondary material is ineffective or only marginally effective for the claimed use, or the generator uses more of it than needed to artificially boost the total amount recycled.

Although we’ve seen that EPA uses the term “waste minimization” to refer specifically to hazardous waste, all facilities can benefit from better general waste management practices. For example, EPA maintains a page called “Managing and Reducing Wastes: A Guide for Commercial Buildings” to help facility managers, building owners, tenants and other stakeholders improve non-hazardous waste management in their buildings, reduce costs and enhance sustainability.

Introducing ESG QuickTakes: A Sustainability E-Newsletter!

Master ESG with our NEW quarterly publication. Get expert insights on regulations, energy management, and sustainability delivered straight to your inbox.

Better Hazardous Waste Management Supports Your EHS to ESG Journey

Our discussion of waste minimization practices above may have us thinking about a connection to sustainability. After all, waste minimization is about reducing risks to human health and the environment, and about reducing regulatory burdens and compliance costs of managing hazardous waste. That’s why these types of programs, along with better environmental management in general, can help get us on the road to Environmental, Social, and Governance (ESG) maturity.

This is especially true if we model our environmental programs on the guidance in ISO 14001, the international standard for environmental management systems. One of the ways the Standard can help is by urging organizations to identify its most significant environmental aspects (Sec 6.1.2), which for an LQG would include hazardous waste. This type of “aspects and impacts” analysis is essentially a form of risk assessment and overlaps with the concept of a materiality assessment, which is a filter to determine the risks and opportunities most important to a company and its stakeholders. From there, you can select and manage relevant objectives for your environmental management system.

Setting Good Objectives, Targets and Programs

Let’s see how this works by looking at the common way of thinking about objectives as defined by ISO 14001, in a system of “Objectives, Targets and Programs.”

Objectives

Objectives are just goals that you’d like to meet in the future. In other words, when you’re writing an objective, even though you should already be thinking about how you’re going to measure and verify them, you’re not going to get that granular yet.

Targets

Targets are the point where granularity comes in. Setting targets involves determining specific verifiable measures to document that you’re meeting your objectives and meeting the chosen performance criteria.

Programs

Programs are the specific methods and strategies you’re going to use within your environmental management system to achieve your objectives and targets.

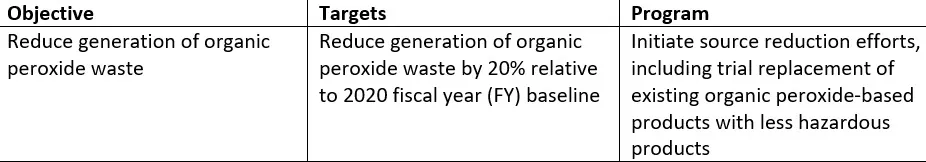

An organization selects Objectives, Targets and Programs based on its assessment of material impacts. For example, suppose our facility is a large quantity generator (LQG) because of the volume of corrosive waste generated per month. There are administrative costs associated with LQG reporting we wouldn’t have to incur if we could get our generator status down, say, 20%, and become an SQG. Additionally, this specific waste is an organic peroxide and requires additional treatment, such as stabilization, resulting in greater disposal costs than many other waste streams. For purposes of simplicity, let’s focus on financial costs as our most material consideration.

Now we can create potential Objectives, Targets and Programs based on our materiality assessment:

Of course, the table above is a simplification because a company can have multiple programs supporting a single target. For example, this company may choose additional programs based on other waste minimization strategies, such as circular reuse of organic peroxide product to reduce the amount that becomes a waste.

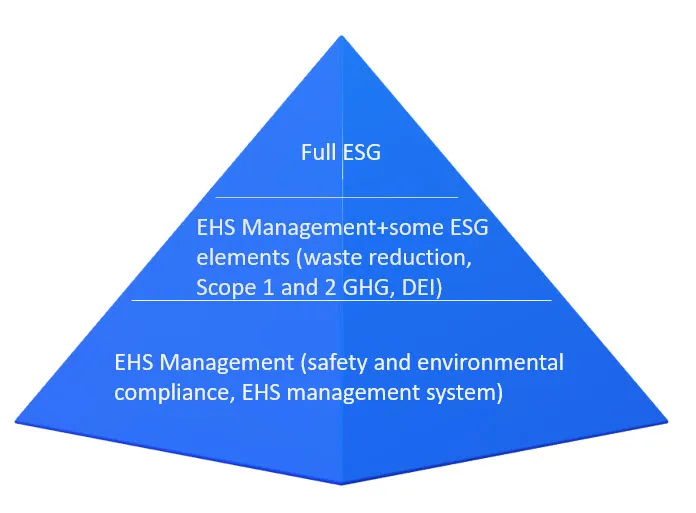

Introducing the ESG Pyramid

Another benefit of using ISO 14001 to shape your waste and other environmental management practices is that you’ll more easily build programs that meet your present needs while anticipating future progress. For example, Section 6.1.3 of ISO 14001 prompts organizations to determine their regulatory compliance obligations, including all the RCRA requirements discussed in this series, and to maintain documentation of compliance status, which would include records and reports required by RCRA or needed for better waste management practices. Sections 4.1 through 4.3 of ISO 14001 also address the need for the organization to consider the needs and expectations of interested parties, the scope of the organization, and its internal and external context – considerations which can lead to evaluations of key ESG elements such as existing disclosure frameworks and expectations of the community in which the business operates.

In other words, this perspective can help a company establish a resilient, adaptable management system that evolves in step with its EHS/ESG maturity level. It helps establish a firm foundation in the basics of EHS management, like hazardous waste reporting and documentation, upon which they can start building ESG programs for waste reduction and sustainability. The “ESG pyramid” below shows the relationship between EHS and ESG management.

Modern ESG software can help you complete the basic environmental management tasks at the base of the pyramid such as waste reporting, management of waste profiles and tracking of manifests, while also facilitating completion of materiality assessment surveys of key stakeholders to identify the issues most important to your ESG progress.

Looking for Additional Resources?

If you’re looking for more information about how to improve your waste management practices, we have you covered.

If you’d like to get a better handle on basic hazardous waste management responsibilities for your generator status, download our guide Cradle-to-Grave: Fundamentals of Hazardous Waste Management.

As discussed above, many generators of hazardous waste also are subject to EPA TRI/Form R reporting requirements and would need to quantify and provide details about the TRI-reportable chemicals shipped as wastes during the reporting year. Our on-demand webinar EPA Toxic Release Inventory Reporting: How to Ensure Compliance can help you better understand TRI reporting applicability and the benefits of EHS/ESG software for reporting TRI required information like hazardous waste release, recycling and shipment details.

EHS managers eager to learn more about how an EHS/ESG management system patterned on ISO 14001 can help them establish a solid foundation in environmental compliance and advance their progress toward ESG maturity should download our guide An Overview of ISO 14001: Using the Standard to Improve Environmental Management. You can also watch our on-demand webinar on the same subject.

And as always, please feel free to follow us on LinkedIn, where you’ll get the latest updates on the worlds of EHS and ESG, including news about regulations and industry developments that will help you continue your career development as an EHS professional.

Let VelocityEHS Help!

The Waste Management capabilities included with VelocityEHS Environmental Compliance Solutions help you simplify every facet of hazardous waste management including tracking of hazardous waste manifests, generation of EPA-required hazardous waste reports (HWRs), reporting to support internal waste minimization efforts, and maintain all of your waste profiles in a single, easily accessible system. You’ll also be able to report on waste by type and quantity, monitor waste shipment transit time, and analyze your costs by time, type of waste, or vendor.

If you’re ready to see how VelocityEHS can help streamline your hazardous waste management program, Request a Demo or contact us today for more information about how to do EHS and ESG right.