Welcome to the second installment of our ongoing blog series “Introduction to Hazardous Waste.” In this edition, we’ll cover the basics about how to determine your hazardous waste generator status, and describe the main requirements for each type of generator. If you missed the first post in this series and want to catch up on the process for determining if your wastes are hazardous, don’t worry – you can still check out that post right here.

Guide to Hazardous Waste Management Part One: Do You Generate Hazardous Waste?

If you’re ready, let’s carry on with a deeper dive into the steps involved in determining your hazardous waste generator status and identifying your key compliance obligations.

What is a Hazardous Waste Generator?

Let’s begin our discussion by covering how to identify if your facility is a hazardous waste generator.

According to EPA, a generator is any entity which produces a hazardous waste as listed or characterized in part 261 of title 40 of the Code of Federal Regulations (CFR).

This means that the first step is to determine if any of your wastes are hazardous per EPA’s definition – a process we discussed in the first installment of this series. If any of your wastes are RCRA-defined hazardous wastes, your facility is a hazardous waste generator.

Keep in mind that your specific identification as a generator is determined at the facility level, not the company level. A single company can have some locations that are generators of hazardous waste, and some that are not.

Facility-Specific Information

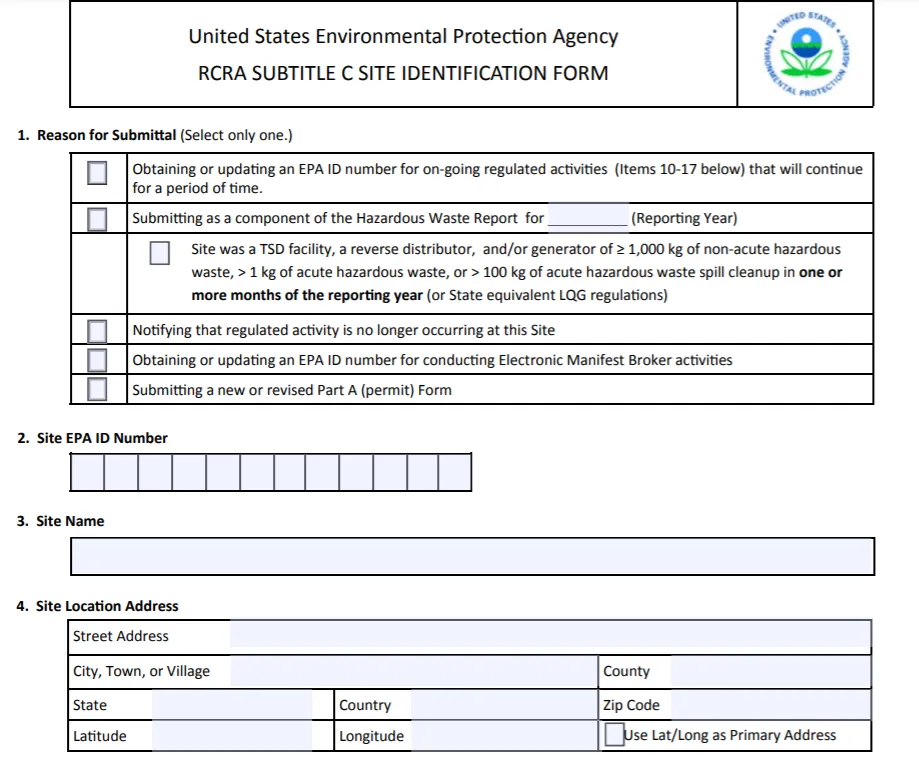

Depending on your generator status and on state requirements (as determined below), you may need to formally obtain an EPA hazardous waste generator identification number by completing the RCRA Subtitle C Site Identification Form (Form 8700-12) and submitting to the authorized state agency or federal EPA regional office.

The RCRA Subtitle C Site Identification Form includes facility-specific information such as:

- Facility’s name and address;

- Contact information; and

- A description of hazardous waste activities conducted at the site

Some of the information you’ll need to include on the form is shown in the image below.

There are a number of other situations other than initial notification of hazardous waste activity in which you may need to submit this form. Some of those situations include a change in facility ownership, if your facility changes location, if you cease hazardous waste activities or close your facility, or initiate other hazardous waste activities such as on-site hazardous waste recycling or on-site treatment, processing or burning of used oil. A complete list of activities triggering notification and re-submission requirements is provided in the instructions for Form 8700-12.

Hazardous Waste Identification Example: Parts Washer Solvent

Before moving on to discuss how you determine your hazardous waste generator status, I want to address some specific issues pertaining to parts washer solvent. It’s a common waste product in many facilities and I know it can sometimes be confusing to determine if parts washer solvent is hazardous. There are times a facility’s only potentially hazardous waste may be parts washer solvent, and so the question of whether the facility is a hazardous waste generator comes entirely down to correctly classifying the spent solvent.

There are really two main considerations to take into account:

Flash Point

Do you know flash point of the fresh solvent as supplied, or do you have analytical results for the flash point of the spent solvent? As discussed in our first installment, a waste is hazardous based on the ignitable characteristic if it has a flash point of less than 140 degrees Fahrenheit.

Is it Actually Considered ‘Waste’?

If your solvent is contained in a parts washing unit provided to you and/or serviced by a contracted service provider, does the contractor manage your spent solvent under a re-use agreement? What this means is that after picking up your spent solvent, they may use it as a product for purposes such as cleaning tanks or equipment at their facility. By definition, this means it’s not a waste and also means it’s not a hazardous waste. Many large service providers offer such agreements, which benefits them as well as their customers since the spent solvent does not count as hazardous waste or affect the originating facility’s generator status. If you’re unsure if you have such an agreement in place, contact your service provider and save a copy of the agreement (if it exists) with your other waste program documents, such as your profiles.

How to Determine Your Generator Status

Your generator status is determined by the combined volume of hazardous waste your facility generates within a calendar month. Use the table below to determine your generator status.

| Generator Status | Quantity Limit |

| Very Small Quantity Generator (VSQG) | ≤100 kg/month, and ≤1 kg/month of acute hazardous waste, and ≤100 kg/month of acute spill residue or soil |

| Small Quantity Generator (SQG) | >100 and <1,000 kg/month |

| Large Quantity Generator (LQG) | ≥1,000 kg/month, or >1 kg/month of acute hazardous waste, or >100 kg/month of acute spill residue or soil |

Keep in mind that the table above lists only the federal EPA generator classification levels. Some state EPAs may have different criteria from the federal requirements, so be sure to check on the thresholds for generator status within the state(s) of operation for your facilities(s). EPA’s table linked here notes the states that have generator categories different from the federal categories.

Episodic Waste Generation Events

What if you have an episodic event – a planned or unplanned circumstance such as a cleanout, spill cleanup, or disposal of excess or outdated product? For many years, episodic events posed a vexing problem because while they are commonly necessary and unavoidable, they could cause a hazardous waste generator to either be out of compliance or ultimately classify them under a higher generator status that’s not representative of their typical waste generation activities or quantities.

EPA recognized this difficulty due to stakeholder input, and made it one of the key areas addressed by the 2016 Hazardous Waste Generators Improvement Final Rule. The rule establishes a set of regulatory guidelines through which VSQGS and SQGs can maintain their current generator status if an episodic event occurs. The key provisions for VSQGs and SQGs are very similar and include requirements to:

- Notify the EPA no later than 30 calendar days prior to a planned event or within 72 hours of an unplanned event, using Form 8700-12

- Accumulate hazardous waste in properly marked and closed containers or tanks

- Ship waste within 60 calendar days from the start of the episodic event. SQGs that treat waste must do so within the same 60-day window

- Maintain records for 3 years from the end of the episodic event that describes the event, the type and quantity of hazardous waste generated, a description of how the waste was managed and the name of the transporter

What if a VSQG or SQG that has already had a planned episodic event recognizes the need for another? The allowances provided by the 2016 final rule let them petition for a second unplanned episodic event within the same calendar year, provided they do so within 72 hours of the unplanned event. The VSQG or SQG must make their petitions to their Regional EPA Administrator, and must include:

- Reason(s) why they will need to have an additional episodic event

- A description of the nature of the event

- A description of the time that will be needed to manage the hazardous waste generated by the event; and

- Information about the previous episodic event, including the nature of the event and how it was managed

Generators can make these petitions electronically or by mail. If the EPA administrator grants the petition, the facility must maintain records for 3 years from the end date of the episodic event.

More information about allowances and requirements for episodic events can be found at EPA’s FAQ page about the 2016 final rule. At this page, you’ll find a summary of the rule, details about its history, and resources to assist with compliance, as shown in the screen capture below.

Hazardous Waste Generator Compliance

Now that we know how to determine your generator status, let’s take a look at the specific requirements for each type of generator.

Very Small Quantity Generators (VSQGs)

As we’ve already seen in the table above, VSQGs generate 1 kilogram (kg) per month or less of hazardous waste and must also generate 1 kg or less of acute hazardous waste, which EPA considers to pose a significant threat to human health and the environment even under proper management.

All discarded, unused commercial chemical products on the P-list at §261.33(e) and mixtures or formulations containing the chemical as a sole active ingredient are acute hazardous wastes. Used or spent process wastes on the F-list at 40 CFR 261.31 and identified with a hazard code “H” are also acute hazardous wastes. More information about listed hazardous wastes including the P and F lists is provided in the first installment of this series.

Major requirements for VSQGs include:

- VSQGs must identify all the hazardous waste generated.

- VSQGs may not accumulate more than 1,000 kilograms of hazardous waste at any time.

- VSQGs must ensure that hazardous waste is delivered to a person or facility who is authorized to manage it.

Notice that federal EPA regulations do not require VSGGs to obtain a generator identification number, but per our discussion of episodic generation events above, VSQGs would need to submit Form 8700-12 no later than 30 calendar days prior to a planned event or within 72 hours of an unplanned event.

The same 2016 final rule that provides new allowances for episodic events also changed the name of this generator status from the old term “Conditionally Exempt Small Quantity Generator (CESQG)” to VSQG. The rule enables VSQGs to send hazardous waste to a large quantity generator (LQG) that is under the control of the same person and consolidate it there before sending it on to management at a RCRA-designated facility, as long as certain conditions are met. This allowance is meant to reduce the management and compliance burden for VSQGs, as well to reduce operating costs to the company and improve waste management and recycling by consolidating hazardous at LQG facilities with more stringent requirements.

Small Quantity Generators (SQGs)

SQGs generate more than 100 kgs, but less than 1,000 kgs of hazardous waste per month. Major requirements for SQGs include:

- SQGs may accumulate hazardous waste on-site for 180 days without a permit (or 270 days if shipping a distance greater than 200 miles).

- The quantity of hazardous waste stored on-site must never exceed 6,000 kilograms.

- SQGs must comply with the hazardous waste manifest requirements at 40 CFR part 262, subpart B and the pre-transport requirements at 40 CFR sections 262.30 through 262.33.

- SQGs must manage hazardous waste in tanks or containers subject to the requirements found at 40 CFR sections 262.16(b)(2) and (3).

- SQGs must comply with the preparedness and prevention requirements at 40 CFR sections 262.16(b)(8) and (9), and the land disposal restriction requirements at 40 CFR part 268.

- SQGs must file exception reports if “return receipts,” or copies of signed manifests from the treatment, storage and disposal facilities (TSDFs) are not received

- SQGs must inspect central accumulation areas for hazardous wastes on an at least weekly schedule. The inspections must specifically look for leaking containers and for deterioration of containers caused by corrosion or other factors.

- SQGs must always have at least one employee available to respond to an emergency. This employee is the emergency coordinator responsible for coordinating all emergency response measures. SQGs are not required to have detailed, written hazardous waste contingency plans like LQGs must (see section about LQGs below). However, many SQGs elect to have a written contingency plan anyway as a best management practice.

SQG operators should note that the Hazardous Waste Generator Improvements Rule established a requirement for all hazardous waste SQGs to re-notify EPA of their hazardous waste activities every four years. The purpose of the re-notification requirement is to improve EPA’s data regarding SQGs, which will help improve the agency’s efforts in outreach, compliance assistance and oversight activities.

The first re-notification deadline following implementation of the rule has already passed (September 1, 2021). All future re-notification deadlines will follow at 4-year intervals from that initial deadline (e.g., September 1, 2025, September 1, 2029, etc.) You can find more information about the SQG re-notification requirement here.

Large Quantity Generators (LQGs)

LQGs generate 1,000 kgs per month or more of hazardous waste, or more than 1 kilogram per month of acutely hazardous waste. Major requirements for LQGs are as follows:

- LQGs may only accumulate waste on-site for 90 days, although certain exceptions apply. This means that LQGs need to closely monitor their hazardous waste accumulation times to avoid exceedances of the 90-day limit.

- LQGs do not have a limit on the amount of hazardous waste accumulated on-site.

- LQGs must manage their hazardous wastes in tanks, containers, drip pads or containment buildings subject to the requirements found at 40 CFR sections 262.17(a)(1)-(4) and, specifically for drip pads and containment buildings, 40 CFR part 265, subparts W and DD, respectively. This requirement is intended to reduce the potential for releases of hazardous waste that may impact the environment and human health.

- LQGs must comply with the hazardous waste manifest requirements at 40 CFR part 262 subpart B and the pre-transport requirements at 40 CFR sections 262.30 through 262.33.

- LQGs must file exception reports if “return receipts,” or copies of signed manifests from the treatment, storage and disposal facilities (TSDFs) are not received

- LQGs must comply with the preparedness, prevention and emergency procedure requirements at 40 CFR part 262 subpart M and the land disposal restriction requirements at 40 CFR part 268.

- LQGs must submit a biennial hazardous waste report.

- Ensure appropriate training for employees who handle or manage hazardous waste, via classroom or on-site instruction, to become familiar with proper hazardous waste management and emergency procedures for the wastes handled at the facility.

- LQGs must inspect central accumulation areas for hazardous wastes on an at least weekly interval. The inspections must specifically look for leaking containers and for deterioration of containers caused by corrosion or other factors.

- LQGs must have a waste minimization program in place to certify steps taken to reduce or eliminate the generation of hazardous waste

You can probably see from the above that LQGs have the most stringent requirements, which makes sense because with larger volumes of hazardous waste generated and stored, there’s a lot more at stake. That’s one reason why many generators find it in their best interests to keep their waste generation levels below the LQG threshold, or to reduce their levels to drop down to a lower status.

Common Requirements for All Waste Generators

There is quite a bit of variability in requirements across the three RCRA generator statuses, as we’ve seen. Even so, we should note that there are some core requirements that apply to all generators of hazardous waste, regardless of status:

- Characterization of wastes. All generators of waste must determine which of their wastes are classified as hazardous, based on the criteria discussed in our first installment in this series. We can see that it’s also important to be sure we’re identifying acute hazardous wastes, since even a small quantity of acute waste generated per month (≤1 kg) will trigger generator status and compliance obligations.

- Determination of generator status. All generators are responsibility for accurately determining their generator status based on the classification criteria described above in this article. This is a crucial step that many other compliance responsibilities are determined by.

- Ship wastes to persons or facilities authorized to manage them. Recall that under the Hazardous Waste Generator Improvements Rule, VSQGs can ship their wastes to an LQG facility under the same management. In all other cases, facilities must ship their hazardous wastes to licensed and approved facilities.

- Cradle-to-grave responsibility. This responsibility encompasses and summarizes all of the preceding three. If your facility generates hazardous waste, you are ultimately responsible for it from the time of its generation until its disposal—and in the event of a release at a facility not properly licensed or prepared to store and treat wastes, potentially even long after that. You can minimize your potential for liability by accurately characterizing and effectively managing your wastes, and ensuring that you’re shipping all hazardous wastes to facilities or persons authorized and qualified to handle them.

We could take a step beyond the regulatory requirements, and make the case that inspections are a common necessity for all generators, too. While RCRA does not give VSQGs the same weekly inspection requirement that SQGs and LQGs have, VSQGS nonetheless may have a difficult time ensuring that their waste containers are not leaking or compromised, or are not accumulating more than 1,000 kg of waste at a time (per VSQG requirements) if they’re not doing regular inspections.

A big takeaway here is that you’re never too small to need better support managing hazardous waste. Better tools for managing hazardous waste profiles, tracking accumulation times and waste shipments, and reporting on hazardous waste for internal or regulatory reporting can give you the visibility and control you need, no matter your generator status.

Looking for More Information?

There are a number of great resources available covering management of hazardous waste and compliance with RCRA regulations. Check out EPA’s generator-specific fact sheets on VSQGs, SQGs, and LQGs. EPA has also prepared a training module called “Introduction to Generators” that covers responsibilities for all categories of waste generators.

For more information about the requirements brought into effect through the 2016 Hazardous Waste Generator Improvements Rule, check out our VelocityEHS on-demand webinar via the link below.

Managing Waste under the New Hazardous Waste Generator Rule – Strategies for Success

And of course, be sure to follow this space and follow us on social media to catch future installments of our ongoing Introduction to Hazardous Waste blog series!

Let VelocityEHS Help!

Looking for a way to improve your hazardous waste management programs? VelocityEHS can help! The Waste Management capabilities included with VelocityEHS Environmental Compliance Solutions help you simplify every facet of hazardous waste management including tracking of hazardous waste manifests, generation of EPA-required hazardous waste reports (HWRs), reporting to support internal waste minimization efforts, and maintain all of your waste profiles in a single, easily accessible system. In addition, our Inspections software enables you to create a site-specific waste inspection template that you and your people can use to inspect your waste accumulation areas.

To see how VelocityEHS can help streamline your hazardous waste management program, Request a Demo or contact us for more information.