Welcome to Part Three of our ongoing series, “Introduction to Hazardous Waste Management.” In case you missed the previous installments, please check out Part One to review how to determine if your waste is hazardous, and Part Two for a primer on how to determine your generator status and associated compliance obligations.

Throughout this series, we’ll unpack the major federal requirements for generators of hazard waste. Keep in mind that state requirements may be more stringent, and that you’ll have additional requirements if you’re permitted to store hazardous wastes.

Now, let’s talk about the basics of managing hazardous waste on-site.

Labeling Hazardous Waste Containers

Labelling your containers of hazardous waste is essential to your program, because you can’t meet your other responsibilities unless you know which containers hold hazardous wastes.

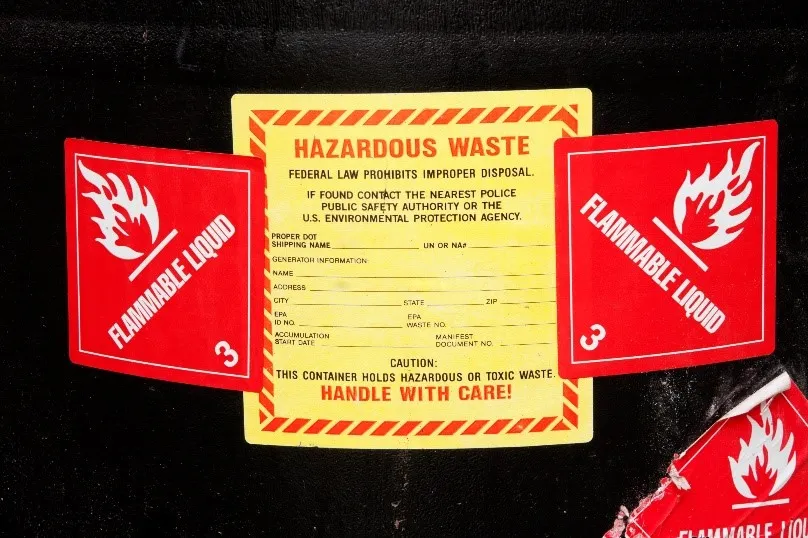

Not surprisingly, RCRA has established requirements for labelling hazardous wastes. Per RCRA regulations, generators who are accumulating hazardous waste must affix labels containing the following elements to each container of waste:

- The words “Hazardous Waste”

- The “date upon which each period of accumulation begins,” or as it’s commonly known, the “accumulation start date”

- An indication of the specific hazards of the waste, such as:

- EPA waste codes or names for waste characteristics

- Department of Transportation (DOT) pictograms for the associated hazard class/division

- A hazard label consistent with National Fire Protection Association (NFPA) Standard 704

- A hazard pictogram consistent with OSHA HazCom requirements

Here’s an example of a sample hazardous waste container label and DOT Class 3 Flammable Liquid labels.

Keep in mind that, consistent with this entire series, we’re only talking about requirements for generators accumulating wastes in accordance with the requirements to avoid coverage under a permit to store wastes. Facilities such as treatment, storage and disposal (TSDF) operations would have different and more stringent requirements, including more specific labeling requirements.

Tracking Accumulation Times

Note that one of the elements of a hazardous waste label is the “accumulation start date.” This is an important detail to track, because one of your major compliance tasks is to ensure that your total hazardous waste accumulation times don’t exceed the limits allowable for your generator status. For a review on how to determine your generator status, check out our last installment of this series.

Let’s first clarify when “accumulation” begins, because even many EHS professionals lack clarity on this issue. According to EPA, the accumulation clock starts when the filling of a container in a central accumulation (CAA) area begins, or when a filled container from the satellite accumulation area (SAA) is brought to the CAA. The CAA, as the name indicates, is the main area where a generator accumulates hazardous waste prior to shipment. Often, the generator situates a CAA within a storage room or other secondary containment structure, like the room shown below. We’ll discuss SAAs and their relationship to CAAs shortly.

RCRA does not establish accumulation time limits for very small quantity generators (VSGQGs), but VSQGs need to ensure their waste generation totals don’t put them into a higher generator status that does have established accumulation time limits. Let’s talk more about those time limits now.

Small Quantity Generators

Small quantity generators (SQGs) can accumulate wastes on-site for no more than 180 days without a storage permit. However, an SQG has a couple of specific allowances:

- An SQG can accumulate hazardous waste on-site for up to 270 days if its treatment, storage and disposal facility (TSDF) is located 200 miles away or more from its facility. The SQG wouldn’t need prior approval from the EPA or state EPA with jurisdictional authority, but it would be in their best interests to have documentation on-hand to not only show that the TSDF is 200 miles or more away, but also to justify reasons why you selected such a distant TSDF, such as their ability to treat the wastes we ship them.

- An SQG can accumulate hazardous waste on-site for longer than the 180- or 270-day deadlines if they receive an extension by the EPA or state EPA. If granted, an extension provides an additional 30 days of on-site storage time. In requesting the extension, the SQG needs to describe the “unforeseen, temporary, and uncontrollable circumstances” that necessitate storing the wastes on-site past the established deadlines. The agency will evaluate and if warranted, approve extensions on a case-by-case basis.

Large Quantity Generators

A large quantity generator (LQG) can accumulate hazardous waste on-site for up to 90 days without a storage permit. RCRA provides the following specific allowances to LQGs:

- If the TSDF is located 200 or more miles away, they can extend on-site storage time to 270 days (the same allowance that SQGs have).

- LQGS can receive a 30-day extension by applying to the applicable EPA or state regional office and explaining the “unforeseen, temporary, and uncontrollable circumstances” necessitating the extension (also the same allowance that SQGs have).

- An LQG that generates an F006 listed hazardous waste (wastewater treatment sludges from electroplating operations) can accumulate only those F006 listed wastes on-site for up to 180 days, instead of the usual 90-day limit. The LQG doesn’t need to notify the EPA or state EPA first, but they need to comply with the requirements of 262.34(g)(1-4) to take advantage of this exception.

Satellite Accumulation Areas

Another way generators can get extra flexibility with hazardous waste accumulation times is by using SSAs, which are areas near the point of waste generation. Generators can accumulate a limited amount of hazardous waste in SAAs prior to moving them to a CAA, if they meet certain requirements:

- They can accumulate only up to 55 gallons of hazardous waste or 1 kilogram of acute hazardous waste in the SAA;

- They can only accumulate waste in containers, rather than in tanks or containment buildings, or on drip pads;

- The container(s) must be under the control of the operator generating the waste;

- The container(s) must be at or near the point of generation of the waste; and

- Once you reach the threshold storage level of 55 gallons for hazardous waste or 1 kg of acute hazardous waste in an SSA, you have 3 calendar days to either move the excess waste to your CAA or transport off-site. If you move a container to your CAA, that starts your normal “accumulation clock” and you’ll then have 90 days if you’re an LQG or 180 days if you’re an SQG to keep the waste on site without a permit, unless you use one of the allowances for your generator class to extend the time.

EPA has assembled a useful compendium of regulations and supporting materials pertaining to SSAs (see front cover image below).

There are timing elements to track for SAAs. While RCRA does not require you to record the accumulation start date for containers in your SAA, doing so might help your waste management efforts by giving you a better idea of your waste generation rate, and by indirectly prompting you to check on your waste containers to make sure you haven’t yet reached your accumulation limit. Remember, once you have over 55 gallons of hazardous waste or 1 kg of acute waste, you need to either transport the excess waste to a TSDF or bring it to your CAA within 3 days.

Hazardous Waste Inspections

Sections 262.16 (b)(2)(iv) and 262.17 (a)(1)(v) require SQGs and LQGs, respectively, to conduct weekly inspections of hazardous waste storage areas. Specifically, according to the regulations, hazardous waste generators must look for leaks, damaged and corroded containers, and other integrity issues when conducting their inspections.

Specific additional requirements may come into play depending on the types of containers used for wastes. For example, generators who store hazardous waste in tanks need to meet additional criteria established in Sections 262.16 (b)(3) (for SQGs) and 265.196 (for LQGs). Generators also must meet specific criteria if they accumulate wastes on drip pads, which are curbed secondary containment structures, commonly used in wood preservation operations, designed to convey excess liquids from spillage or surface water runoff to another container. Both LQGS and SQGs must remove wastes from drip pads at least once every 90 days, track accumulation time once they’re in the CAA, and use written procedures and documentations to maintain and demonstrate compliance.

What if an inspection identifies hazardous waste containers in poor condition? RCRA requires both SQGs and LQGs to immediately transfer hazardous waste from leaking or damaged containers to containers in good condition. That means our hazardous waste inspections need to lead to well-managed corrective actions to support effective hazardous waste management in compliance with RCRA regulations.

While RCRA does not establish specific inspection requirements for VSQGs, operators of VSQG facilities have the same “cradle to grave” responsibility for wastes that all generators have. Therefore, it’s in their best interests to perform regular inspections.

The specific elements to cover during hazardous waste inspections depend on your facility, your wastes and your waste storage practices. That’s why it’s important to put some thought into how to structure a site-specific inspection checklist for your facility. Modern EHS software makes it easy to develop a site-tailored inspections checklist that you and your people can deploy in the field using mobile devices, so you can be sure to inspect the right things the right way.

Hazardous Waste Training

RCRA establishes training requirements for hazardous waste generators. The specific details to include depend on your generator status, and on the job responsibilities of your employees for managing wastes.

Let’s look at specific training requirements for each generator category.

LQGs

LQGs have the most stringent training requirements. 40 CFR 265.16 requires LQGs to provide hazardous waste training to all “personnel” who work with hazardous wastes, and is very specific about required elements of a training program.

The program must consist of either classroom instruction or “on-the-job-training” designed to teach employees how to perform their job duties in a way that “ensures compliance” with hazardous waste regulatory requirements, and must include procedures relevant to employee positions and roles.

The person providing training must be someone trained in hazardous waste management procedures.

The training must include details needed to ensure that facility personnel are familiar with emergency response plans and equipment, including (where applicable) inspection and repair procedures for emergency response equipment, parameters for automatic waste feed cutoff systems, communications and alarm systems, responses to fires or explosions, responses to groundwater contamination incidents, and operation shutdown procedures.

SQGs

40 CFR 262.16(b)(9)(iii) requires SQGs to train employees who handle hazardous wastes as part of normal operations and emergencies to be “thoroughly familiar” with hazardous waste operations relevant to their job duties.

That “relevant to their job duties” phrase says a great deal in its brevity. Only you as an employer, based on your knowledge of job tasks and hazardous waste management practices, can determine what employees across specific roles would need to know about hazardous waste to safely do their jobs. For example, do they transfer waste? Do they move closed containers from SAAs to CAAs? Do they interact with waste contractors who remove and ship wastes and sign manifests? Incorrect information on manifests can create liability for the company.

Engagement with your workers is a key consideration. Make you’re consulting with the employees responsible for managing waste to make sure you’re capturing the key aspects of their work in your training materials.

VSQGs

RCRA does not spell out training requirements for VSQGs as it does for LQGs and SQGs, but that doesn’t mean that VSQGs have free rein to ignore hazardous waste training.

For example, while RCRA has the least stringent requirements for VSQGs, it still requires them to properly identify solid and hazardous wastes and dispose of wastes. If your facility is a VSQG, you should ask yourself how you’d possibly ensure that you’re meeting those requirements if you’re not providing hazardous waste training? The bottom line is that no matter your generator status, you’re going to want to do some level of training and information-sharing.

Hazardous Waste Contingency Plan

RCRA requires LQGs to develop and maintain a written hazardous waste contingency plan. The purpose of the contingency plan is to describe actions that facility management and personnel will take “in response to fires, explosions, or any unplanned sudden or non-sudden release of hazardous waste or hazardous waste constituents to air, soil, or surface water at the facility.”

You might notice that many of the required components of a contingency plan seem to line up with the required elements of hazardous waste training discussed earlier. A big takeaway there is that your contingency plan should be well-aligned with your training program and should itself be a source of content for training.

You may be required to have other emergency plans depending on applicability of other regulations, such as EPA Spill Prevention Countermeasure and Control (SPCC) plan requirements. If so, EPA doesn’t require LQGs to have a completely separate contingency plan from those other plans, but instead allows them to have a single plan that meets all requirements, as long as it includes the mandatory hazardous waste contingency provisions.

Remember, some states require SQGs to have contingency plans, too. And even if you’re not required to have one, it’s a good idea to at least make sure your existing emergency plans account for your hazardous waste storage and management practices.

Key Points About On-Site Hazardous Waste Management

Let’s recap some of the key takeaways about managing your on-site hazardous wastes:

- Labeling containers of hazardous waste is in many ways “ground zero” for waste management.

- Hazardous waste inspections are important for identifying and correcting issues with your waste containers. Tailor your inspections to your waste generation and management practices at your facility.

- Hazardous waste training is how you ensure that your employees understand your hazardous waste management practices, which in turn helps you meet your regulatory obligations.

- If you’re required to have a contingency plan, make sure it’s well-synced with your other emergency plans. In fact, it’s a good idea to have emergency plans informed by your hazardous waste management practices even if RCRA doesn’t require you to have a contingency plan.

Stay tuned for future installments of this series, in which we’ll talk about hazardous waste shipping and manifest requirements, and how to improve your external and internal waste reporting.

Let VelocityEHS Help!

Looking for a way to improve your hazardous waste management programs? VelocityEHS can help! The Waste Management capabilities included with VelocityEHS Environmental Compliance Solutions help you simplify every facet of hazardous waste management including tracking of hazardous waste manifests, generation of EPA-required hazardous waste reports (HWRs), reporting to support internal waste minimization efforts, and maintain all of your waste profiles in a single, easily accessible system. In addition, our Inspections software enables you to create a site-specific waste inspection template that you and your people can use to inspect your waste accumulation areas.

To see how VelocityEHS can help streamline your hazardous waste management program, Request a Demo or contact us for more information.