Table of Contents

At the heart of every occupational health and safety (OH&S) regulation and management system standard is the goal of identifying and controlling workplace hazards. Job Safety Analysis (JSA) is one of the most valuable and essential tools for achieving this goal, providing safety professionals with a structured approach to identifying, assessing, and controlling job hazards and risks. JSA not only simplifies compliance with occupational health and safety requirements but also helps establish a proactive stance toward workplace safety, foster a culture of safety within the organization, and ultimately reduce injury and illness costs to the business. JSA is an OH&S management tool that every organization should be utilizing to its maximum potential, but many organizations are unfortunately limited by the systems they use to perform and document them.

The Job Safety Analysis (JSA) Process

Effective JSA follows a standardized and well-defined process, starting with job selection and prioritization based on injury frequency, risk levels, and changes in job processes. Selected jobs are then broken down into individual tasks or steps, ensuring each step is clearly defined and manageable. This breakdown facilitates the next step of identifying specific hazards associated with each task, which are then documented and assessed for risk. The risk assessment step involves evaluating the likelihood and severity of hazards, often using a risk matrix to assign risk scores, determining appropriate controls to mitigate identified risks. Lastly, after we’ve had an opportunity to observe the effectiveness of those controls, we should review the JSA to ensure it is comprehensive, up-to-date, and accurate.

JSA Hazard Controls: Where the Rubber Meets the Road

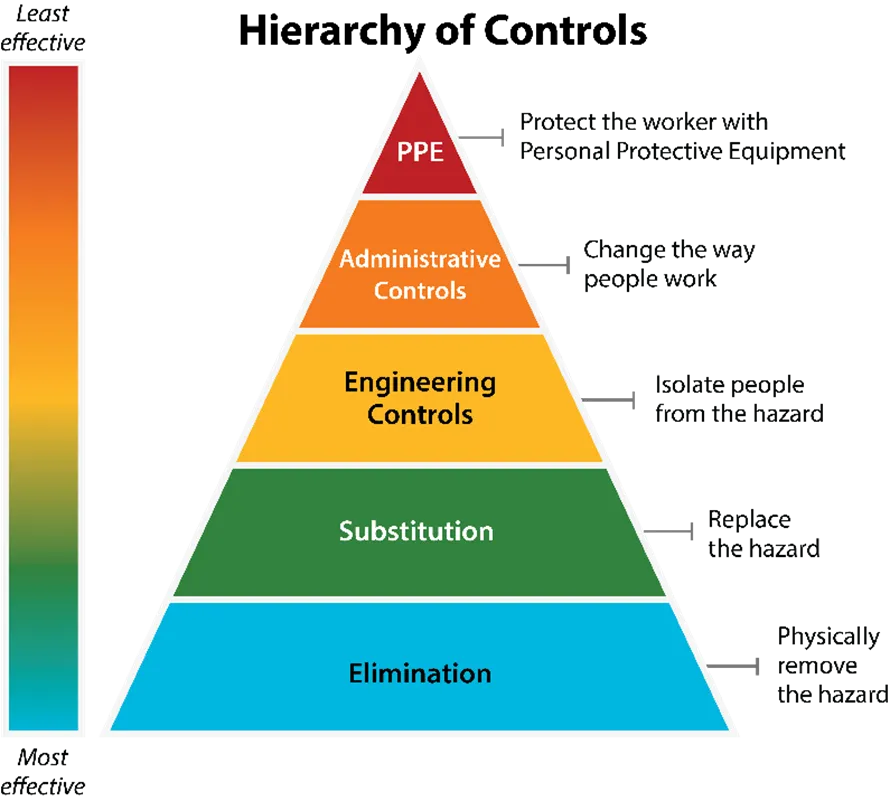

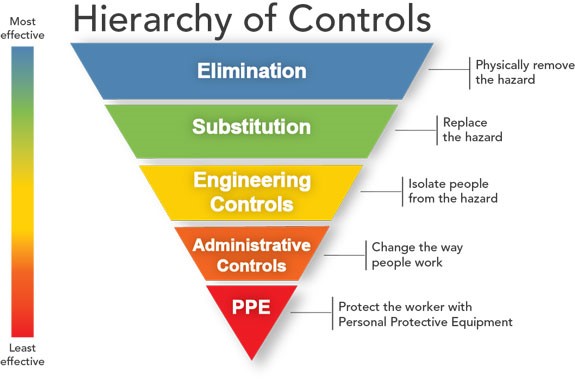

Each step in the JSA process is vital, setting the stage for the success of following steps, but selecting and implementing controls is a particularly critical phase. Controls should be selected based on their appropriateness for the target hazard(s) and effectiveness in eliminating or minimizing hazards. When selecting hazard controls, always follow the hierarchy of controls from elimination to personal protective equipment (PPE). Multiple controls may be necessary for adequate protection, and their effectiveness should be regularly reviewed and updated. This continuous improvement cycle ensures JSA remains relevant and effective in addressing workplace hazards. Regular reviews and updates help identify gaps or areas for improvement, contributing to a safer work environment.

Common JSA Failures

The effectiveness of your JSA can be impacted by many factors including difficulty communicating JSA findings, lack of standardized methods and processes, and subjectivity in risk evaluation and assessment, just to name a few. The 2023 study Applications, Shortcomings, and New Advances of Job Safety Analysis (JSA): Findings from a Systematic Review analyzed 49 separate studies concerning workplace injury and illness investigations and highlighted the most common JSA failures. Addressing these challenges requires a firmly established system for managing JSAs that applies standardized risk assessment criteria, centralized documentation, and effective communication channels. Ultimately, a well-implemented JSA helps better protect workers and contributes to the overall success and sustainability of the organization.

- Lack of employee/stakeholder participation

- Failure to apply hierarchy of controls and assess residual risk

- No unified framework for risk assessment/inconsistent assessment techniques

- Lack of an initial comprehensive list of hazards/inability to reference known hazards can result in improper hazard ID

- JSA does not consider recovery measures (i.e. mitigative controls) needed to bring the system back into the normal/safe state

- Doesn’t identify hazards from performing operations out of the predefined task sequence

- Failure to consider hazard interactions and/or cumulative/synergistic risks

- Inability to share & compare JSA findings across worksites/facilities

- Tedious and time-consuming to perform was the most frequent drawback mentioned by studies

Enhancing Employee Safety Engagement Through JSA

JSA is an ideal exercise to help engage your people in your safety program. Therefore, JSA should be a team sport. Engaging a diverse group of employees in the JSA process ultimately drives your safety culture forward while improving the breadth, depth, and quality of JSA data to help enhance safety program performance. When workers are actively involved in identifying hazards and implementing controls, they become more conscious of safety issues and take greater ownership of workplace safety outcomes. This participation is crucial to fostering a strong safety culture where everyone is committed to preventing incidents and injuries.

JSA Review: A Case Study in Continuous Improvement

Regular review of JSAs is a must to ensure that hazard controls and safe work instructions remain current, accurate, and effective. More than that, keeping your JSAs up-to-date and representative of actual workplace conditions and operations helps improve areas of the safety program beyond the JSA including the ability to document and demonstrate compliance, keep workers informed about new/changing job hazards and controls, verify that workers possess the required qualifications and training, and support the accuracy of inspection activities, just to name a few.

Strengthening JSA Systems & Tools

Effective JSA management demands a systematic approach to documenting and maintaining safety analyses. While spreadsheets are often used, they fall short in communication and risk scoring capabilities, as well as the ability to maintain hazard and control libraries. Purpose-built JSA software solutions provide superior functionality for assigning corrective actions, updating hazard and control libraries, and standardizing risk assessment criteria. These software tools enhance and simplify the JSA process, ensuring that safety measures are consistently applied and updated across various locations and jobs no matter who is performing the JSA.

With the VelocityEHS AI Hazard Analyzer and Control Recommendations powered by Vélo, safety teams can surface risks that might otherwise be overlooked and apply proven controls instantly.

Let VelocityEHS Help!

Watch our on-demand webinar Are Your JSAs Good Enough? Don’t Wait for a Workplace Incident to Find Out to get a detailed breakdown of JSA best practices and see how VelocityEHS Operational Risk software provides safety professionals with a flexible, intuitive JSA management tool to more accurately identify hazards, assess risks confidently and consistently, implement and and verify hazard controls, and enhance communication to strengthen worker safety and engagement.

VelocityEHS Operational Risk is just one of the innovative solutions included in the Accelerate® Platform alongside our Safety, Chemical Management and Industrial Ergonomics solutions. Ready to see for yourself how our software can help you? Request a Demo today!