Virtual reality (VR) technology used to be something that you would only see in movies (I’m picturing the virtual combat scene from The Matrix (1999) between Keanu Reeves and Laurence Fishburne). With the advent of VR for video game consoles, it is becoming accessible to everyone in their homes. The first time I used the Oculus headset for PlayStation® I was blown away by two things: how easy it was to be transported into a new reality, and how easy it was to adapt to my new environment. That was a few years ago and now I’m starting to see VR headsets being used in manufacturing environments more often.

Virtual reality technology in a manufacturing environment enables us to simulate how operators will perform manufacturing processes. VR can display virtual images to a user and allow them to “interact” with planned equipment and parts. The key hardware are binocular head-mounted displays which present the new reality with software to track the position and orientation of equipment. This can be helpful when designing new products or equipment for the manufacturing environment. It is especially useful for evaluating maintenance access, jam clearing, roll changes, and other less frequent tasks.

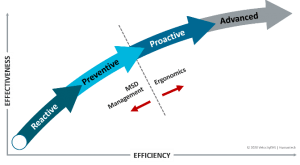

With the introduction of motion-capture technology—the ability to evaluate postures, durations, and frequencies via video without the requirement of wearables—there is an opportunity to combine it with virtual reality in order to move your organization up the Ergonomics Maturity Curve™ (pictured) into being truly “Advanced.”

How can motion-capture technology and virtual reality work together?

The beauty of motion-capture technology is that you are essentially focused on the posture and position of the operator without emphasizing interaction with physical parts. Using video of someone in a virtual environment effectively going through their predicted motions, you can capture postures, durations, and frequencies (assessing the predicted job for musculoskeletal disorder risk) and project the impact of your planned workstation design on the operators who will be exposed to it.

To create a proactive strategy for introducing new products and equipment to the manufacturing facility, make sure you take these types of interactions into consideration and take full advantage of different technologies working together.

Additional Reference:

5 Virtual Reality Applications in Manufacturing. By Ian Wright, Editor, Manufacturing, ENGINEERING.com