By Phil Molé, MPH

Welcome to the third blog in our ongoing series on AI and EHS! In our first post, we provided a general overview of the topic, introducing it to EHS pros curious to learn more about the ways AI can support their life’s work of keeping people safe. Our second post took a closer look at machine learning (ML) and its relevance to EHS professionals like you.

In this latest installment, we’ll revisit the central question of why AI offers a generational opportunity to improve EHS management, focusing on its ability to help quickly assess and control major safety risks.

EHS is About Managing Risks

In the first post in this series, we talked about the fact that EHS professionals know why they do what they do for their life’s work—they want everyone to go home safely every day.

Another way of saying this is that everything in EHS management boils down to managing risks. The ideal situation would be to manage EHS proactively, so we can prevent injuries and workplace accidents from happening instead of just constantly chasing our tails by following up on incidents that have already happened. Unfortunately, the data out there shows that injuries continue to outpace our prevention efforts.

In fact, despite increasing regulatory oversight and the continuing efforts of EHS professionals, the raw numbers and rates of the most severe injuries, involving days away from work (DAFW), restricted duty, or even fatalities, have remained stubbornly high over the past two decades.

In VelocityEHS’s 2023 analysis of OSHA and BLS data, we noted that total recordable case rates, days away, restricted or transferred (DART) case rates, and fatality rates (all normalized based on numbers of employees) increased from 2016 to 2019. The numbers for all three case types then drop in 2020, reach their lowest point in 2021, and then climb partly back toward their previous levels in 2022. Some of the disruptions brought by the pandemic seem to be at play here. The early stages of the pandemic brought significant headcount reductions in the early stages, but there was then rapid growth of payrolls to near pre-pandemic levels, especially during 2021. Some drops in injury rates in this period may be due to reduction in business activity generally, and some of it might be because the hiring rate in 2021 and possibly late 2020 was significantly faster than the injury rate. In other words, because average injury rates are low overall, periods of accelerated workforce growth will significantly “dilute” the rate.

One thing to realize here is that the total recordable incident rate includes all workplace incidents that meet one or more OSHA recording criteria, such as medical treatment beyond first aid, days away from work, etc. But the total incident rate includes several incidents that had more serious risks than the outcome itself may indicate, and which can often get overlooked due to a focus on outcome alone. Many of the trends you’ll learn about now happen due to these “hidden” or underestimated risks.

For example, from 2016 through 2019, while rates for all three case types increased, the rate for DART cases increased significantly faster than the rate for total recordable cases. And during the period from 2021 to 2022, when rates for all three cases bounced up from their low in 2021, the rate for DART cases once again increased significantly faster than the rate for total recordable cases increased.

The fatal work injury rate also rose to 3.6 fatalities per 100,000 full-time equivalent (FTE) workers from 3.4 per 100,000 FTE in 2020, which was also higher than the 2019 pre-pandemic rate of 3.5.

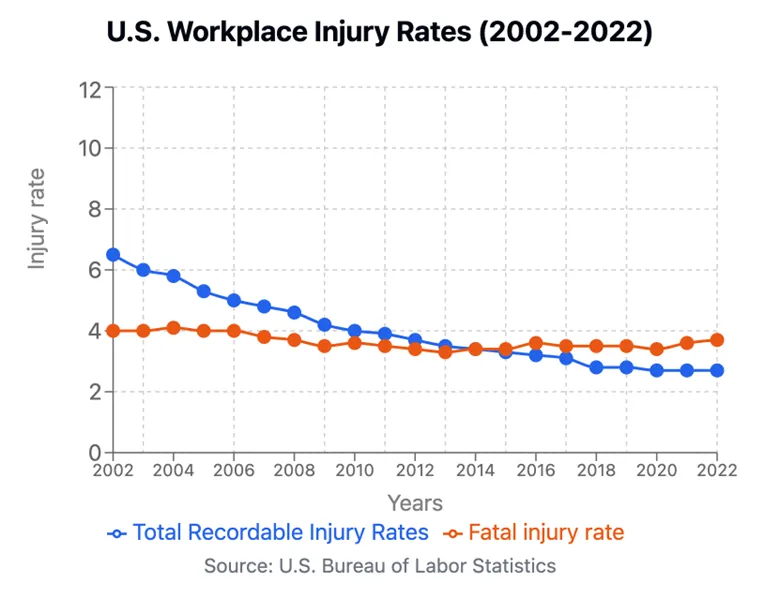

You can get deeper insights into the persistence of this issue by looking at a chart below, which compares total recordable injury rates and fatal injury rates over the 20-year period from 2002 to 2022.

The trends here are telling. The normalized rates for serious incidents—including fatalities, which are the worst possible outcome, increased more than the rates for less serious incidents in recent years. Additionally, the above chart shows that the fatal injury rate has remained extremely consistent between 2002 and 2022. There’s been more success in reducing the rates and numbers of less severe incidents than there has been in reducing fatality numbers. That’s not the expected outcome if we were doing well at assessing risks and addressing them before serious incidents could happen.

We can also see some concerning trends when we take a closer look at the most recent BLS numbers. The chart below shows top industries for restricted duty cases based on 2024 BLS data.

Taken together, the BLS and OSHA data suggest not only that the rate of significant injuries remains stubbornly high, but also that the reason the numbers remain high is because EHS professionals don’t have the resources and bandwidth required to be as proactive as they need to be to assess and control risks before they cause a serious injury.

The lack of proactivity isn’t because EHS professionals don’t want to be proactive. They do, but they have difficulty doing so because time constraints, resource constraints, and inefficiencies in collecting and assessing data make it very difficult to shorten their normal to-do list, let alone shift to a more proactive approach.

As one EHS professional interviewed put it, “I’m doing everything I can, and the injuries are still happening.”

How AI Can Level Up Your Identification and Control of Risks

The BLS numbers don’t lie, and they point to a worrying perseverance in both raw numbers and rates of serious injuries resulting in restricted duty, days away from work or even fatalities.

The key to preventing SIFs is to identify major risks before they can result in major injuries. One of your most important information sources for that is your dataset of workplace incidents, including not only occupational injuries and illnesses but also near misses/close calls, in which an accident could have injured someone but didn’t, at least this time.

It’s a staple of safety management that EHS professionals need to maintain written documentation of these incidents, including a narrative of what happened and how it happened, so they can have the information needed to prevent similar incidents. The importance of this information explains why some regulations (including OSHA’s Recordkeeping Standard in the US) actually require employers to maintain these records.

Of course, having the records and being able to easily use the records are two different things. Chances are, there have been very many incidents at your workplaces, especially if you have large facilities and are responsible for multiple worksites. Assuming you’re doing your job as an EHS professional, that means many incident records, too.

Think about the time it would take to read through all those records, identify the information indicative of the highest risk levels, and put that information into a format that’s accessible and usable. Now, think about the consequences of delays in doing so. Remember, numbers and rates of the most severe injuries remain high in large part because employers are missing some steps in their risk identification process. Also, near misses often fly under the radar, even if they had significant injury potential, partially because no one was hurt, but also because it is very time consuming to investigate each of them for its risks. With significant risks, you can’t afford delays in identifying and controlling them, because the safety and even the lives of your workers literally depend on your ability to control risks as effectively and quickly as possible. Speed matters.

Incident management capabilities with AI driven PSIF detection can make all the difference. Look for software that uses ML/AI to assess your incident records to identify PSIF risks, even when hidden in apparently less “serious” incidents and near misses, so you can prioritize your efforts on controlling those risks. The accuracy of the algorithm reduces potential for human error, and the speed of the process delivers the insights into your most significant risks, helping you to prioritize where you need to make the biggest improvements in workplace safety.

This level of support was not feasible at scale before AI, which helps users move from compliance-driven operations to continuous safety improvement, driven by data and supported by intelligence.

As we discussed a bit in our last post, AI/ML can help with other areas of EHS management, too, including root cause analysis for incidents, description feedback for incident reports and job safety analyses, selection of risk controls, and better-quality ergonomics assessments with more actionable insights.

EHS professionals who take the opportunity to adopt these tools can finally have the support they need to break out of reactive safety management cycles and finally get out ahead of risks.

Ready to Learn More about How AI Can Help You Manage EHS?

Stay tuned for future installments of our AI and EHS blog series, where you’ll learn more about AI, specific use cases for AI in EHS management, considerations when evaluating EHS software and vendors, and more!

In the meantime, you can visit our AI Glossary & Learning Hub to continue learning on your own. There, you’ll find a curated list of resources covering various aspects of AI and EHS, as well as definitions of common terms.

We also invite you to download and read our new white paper, “Why EHS Professionals Can’t Afford to Ignore AI.” You’ll get a deep dive into all of the reasons why EHS pros like you have a generational opportunity to use AI to pivot from a reactive safety management approach to a proactive approach that reduces injury rates and fosters a positive safety culture. From there, you can also get some guidance on what to look for when selecting an EHS software vendor with AI capabilities with our new AI vendor evaluation checklist.

Let VelocityEHS Help!

If you’re ready to jump to the part about how Velocity can help, we’re standing by to talk!

We’d love to tell you more about how our VelocityEHS Accelerate ® Platform powered by Velocity AI and its interactive assistant Vélo can help you end the cycle of struggling to keep up and start the cycle of staying a few steps ahead of hazards and risks.

We’re looking forward to talking about our PSIF Insights, our machine-language powered chemical ingredient indexing, our AI enablement supporting better root cause analysis, better incident descriptions and JSA job task descriptions, better controls selection in ergonomics assessments and JSAs, and auto-processing of contractor documents, just to name a few.

In fact, why not see for yourself how we can help? Get in touch today to set up a meeting so you can see our software in action!