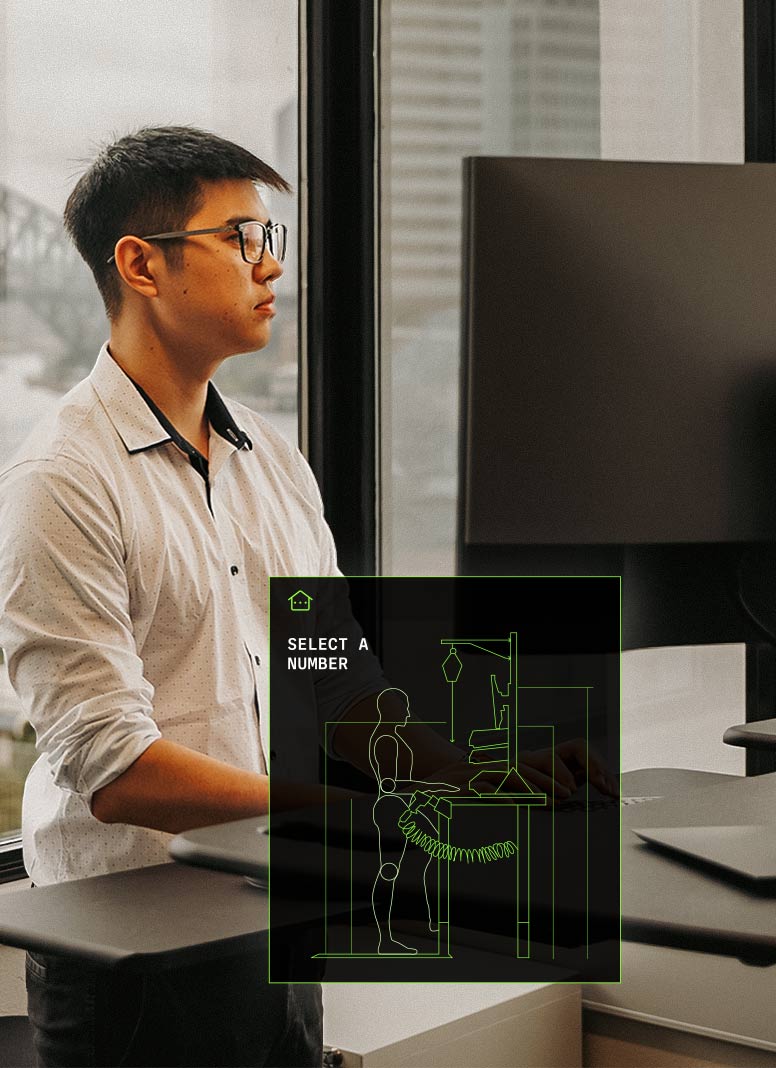

Office Ergonomics

Empowering Engagement for Lasting Impact

Empower your people with intuitive training and self-assessment tools that drive ownership for workstation improvements aligned with ANSI/HFES 100 ergonomics guidelines. Get stronger adoption, centralized visibility, measurable improvements, and greater productivity.

Office Workstation Design

Home Office Ergonomics

Ergonomics Training

MSD Risk Assessment

Ergonomic Equipment Recommendations

Features

- Interactive Online Training

- AI-Driven Assessments

- Workstation/Equipment Recommendations

- Dashboards and Reporting

- MSD Risk Reduction Index

- ROI Summary

Learn More