By Phil Molé, MPH

At the beginning of a new year, there’s a lot to keep track of. It can be hard to get your bearings when it comes to regulatory compliance, especially with all the things you have to tackle on your to-do list.

Never fear! Let’s highlight the 2026 compliance trends that matter most to you.

#1: Shifting Regulatory Priorities from Cuts to U.S. Federal Agencies

In the United States, each new Presidential administration brings a new set of priorities. The current administration has downsized the federal government and pared down regulations.

Some downsizing of OSHA’s staff has already happened, with additional cuts targeted through the FY26 budget. NIOSH, in its research and supporting role, has also had significant cuts, with over 90% of staff reduced in 2025.

With fewer personnel and a smaller budget, OSHA has reprioritized its focus. The agency is still targeting imminent danger situations, fatalities, severe injury reports, and follow-ups for high-gravity serious violations that haven’t been abated. If it’s serious, it’s still getting attention.

During the recent government shutdown, informal conferences and rulemaking were on hold. Employers didn’t have the option of talking through citations and had to either agree to the citation or contest it within 15 working days. We’re still not long past the shutdown of late 2025, and it’s not clear how much headway the agency has made in reducing its backlog of cases, and how that might affect the timing of new cases employers may contest.

Either way, if you get a citation from OSHA, it’s likely to be for something more serious than the citations of years past, so it’s worth thinking carefully about your next steps. If you do agree with the findings of the citation, don’t waste any time abating hazards. Conversely, if you’re contesting, make sure your records, logs, and corrective actions are organized and accessible.

#2: High-Hazard National Emphasis Programs (NEPs)

OSHA NEPs are written statements of policy and procedure on a single subject, which generally include implementation guidelines and responsibilities for the Agency’s affected offices. Why does OSHA use NEPs?

Think of it this way: OSHA is responsible for protecting the safety of employees at all worksites across the U.S. covered under the Occupational Safety and Health (OSH) Act. With all of this to consider, the agency needs to focus enforcement efforts so that it is prioritizing the establishments and work activities with the most significant safety risks. That’s what NEPs do.

It’s important to understand that NEPs do not create any new regulatory obligations or modify any existing regulations. As OSHA states on its page for directives:

“Instructions available here are not standards, regulations, or any other type of substantive rule. No statement in these Instructions should be construed to require the regulated community to adopt any practices, means, methods, operations, or processes beyond those which are already required by the Occupational Safety and Health Act of 1970 (OSH Act) (29 USC § 668), or standards and regulations promulgated under the OSH Act.”

Even so, understanding OSHA’s NEPs gives you important insights into the agency’s enforcement priorities. This understanding helps you, as an employer, know how OSHA is prioritizing which establishments to inspect, a key consideration for a leaner OSHA, and what the Certified Safety & Health Officials (CSHOs) will be looking for once they conduct inspections.

Of the NEPs currently in effect, here are the most recently issued:

Heat Exposure

OSHA issued its NEP on “Outdoor and Indoor Heat-Related Hazards” on April 8, 2022. The NEP lays out OSHA’s inspection and enforcement priorities to support reduction of occupational illnesses and fatalities from heat exposure.

Here’s a high-level overview of the NEP:

Site Selection: OSHA’s NEP contains an Appendix A of “Target Industries for the NEP” that lists the industry sectors, represented by North American Industrial Classification System (NAICS) codes, that they’ll be focusing upon for inspections purposes.

How did OSHA decide which NAIC codes to include? According to the NEP, inclusion of an NAICS in Appendix A results from:

- High numbers or high incidence rates of heat related illnesses from BLS data

- Elevated number of days away from work or high numbers of severe cases of heat-related illnesses, as indicated by death or hospitalization, from OSHA severe injury reports made by employers

- The highest number of heat-related general duty clause 5(a)(1) violations and Hazard Alert Letters (HALs) over a 5-year period (1/1/2017 through 12/31/2021), or the highest number of OSHA heat inspections since 2017

Not surprisingly, Appendix A includes various subsectors of the construction industry. It’s a good idea to identify whether your industry sector is listed in Appendix A, and in general to start proactively identifying and mitigating heat exposure risks in your workplace.

Fall Protection/Prevention

OSHA issued an NEP on April 24, 2023 with the expressed goal to “significantly reduce or eliminate unprotected worker exposures to fall-related hazards in all industries that can result in serious injuries and deaths.”

The “Scope” section of the NEP notes that OSHA will be conducting all inspections related to falls in the construction industry based on the provisions of the NEP. For non-construction inspections, the NEP targets the following activities:

- Roof top mechanical work/maintenance

- Utility line work/maintenance (electrical, cable)

- Arborist/tree trimming

- Holiday light installation

- Road sign maintenance/billboards

- Power washing buildings (not connected to painting)

- Gutter cleaning

- Chimney cleaning

- Window cleaning

- Communication Tower

The NEP also notes that if OSHA inspectors observe employees working at height in other non-construction work activities, they may initiate an inspection if approved by area office management.

According to the NEP, CSHOs are authorized to initiate inspections whenever they observe someone working at heights, and that these observations may occur during the CSHO’s normal work-day travel or while en route to, from, or during, other OSHA inspections. Also, the CSHO may expand the scope of an inspection under this NEP if there is evidence from injury and illness records, plain view hazards, or employee interviews of other potential safety and health hazards or violations at the worksite.

Combustible Dust

OSHA’s revised Combustible Dust NEP became effective on January 30, 2023, and cancels an earlier (2008) combustible dust NEP. The new NEP updates OSHA’s targeting of industry sectors based on current knowledge of combustible dust risks, focusing on the following industries:

- Wood products, including lumber

- Agriculture

- Human food products

- Animal food products

- Chemicals

- Rubber

- Textiles

- Forest and furniture products

- Metal processing

- Tire and rubber manufacturing

- Paper products

- 3-D printing

- Pharmaceuticals

- Wastewater treatment

- Recycling operations (metal, paper, and plastic)

- Coal dust in coal handling and processing facilities

A full list of targeted industries is included in Appendix B of the standard. The NEP indicates that CSHOs conducting inspections pursuant to this NEP will include the following elements:

Plant History of Fires and Explosions: CSHOs will determine whether the establishment has had a history of fires or explosions caused by combustible dust, using techniques, such as employee interviews and observations of buildings and process equipment, including review of OSHA logs, insurance claims, and local fire department records.

Review of Safety Data Sheets (SDSs): The NEP states that CSHOs should review SDSs for information that may indicate a particular dust is combustible. It also cautions that SDSs should be used for initial information only and analytical tests are the only reliable way to determine if dusts at the establishment are combustible.

Review of Electrical Area Classification Drawings/Documents: CSHOs will review information about electrical areas to identify areas delineated as Class II, Division 1 or Division 2 and ensure electrical equipment is approved for the hazardous location.

Review of Employer Dust Hazard Analysis (DHA): The NEP instructs CSHOs to review the DHA the employer has developed and used to identify, evaluate the potential fire, flash fire, or explosion hazards associated with the presence of combustible dust at the establishment.

The CSHOs should also observe all areas of the facility for evidence of buildup of combustible dust and should observe and verify what dust prevention measures the employer may have in place, such as explosion prevention systems on dry dust collectors, spark detection and extinguishing systems on ventilation, and dust reduction features on material handling equipment.

Warehousing and Distribution Center Operations

OSHA issued an NEP for the warehousing/distributions industry on June 14, 2023, which went into effect July 13, 2023. The table below summarizes the specific NAICS codes associated with warehousing/distribution OSHA is targeting under this NEP.

| NAICS Codes | Establishments |

| 491110 | Postal service (processing and distribution centers only) |

| 492110 | Couriers and express delivery services |

| 492210 | Local messengers and local delivery |

| 493110 | General warehousing and storage |

| 493120 | Refrigerated warehousing and storage |

| 493130 | Farm product warehousing and storage |

| 493190 | Other warehousing and storage |

Many warehousing and distribution operations are connected to retail operations. They handle the storage of products until the retail arm of the same company is ready to stock them in their stores. OSHA is aware of this, and its NEP also recognizes that many retail establishments have the same or similar hazards as their warehousing/distribution branches. It provides procedures for conducting partial safety inspections of certain retail establishments with the highest rates of injuries and illnesses. The table below summarizes the high injury rate retail establishments covered under this NEP.

| NAICS Code | High Injury Rate Retail Establishments |

| 444110 | Home centers |

| 444130 | Hardware stores |

| 444190 | Other building material developers |

| 445110 | Supermarkets and other grocery stores |

| 452311 | Warehouse clubs and supercenters |

The NEP covers both programmed (planned and scheduled) and unprogrammed inspections. According to the section on Inspection Procedures within the NEP, each inspection will begin with an opening conference in which the CSHO will verify the NAICS code of the establishment and verify the location where warehousing and distribution activities occur.

Hazardous Machinery

This most recently issued of OSHA’s NEPs, on hazardous machinery, went into effect in June 2025 and replaces a prior NEP on amputations issued in 2019.

The purpose of the NEP is to identify and reduce or eliminate amputation hazards in manufacturing industries by directing OSHA inspection resources toward workplaces where amputation risks from machinery and equipment are highest. The “hazardous machinery” title reflects the fact that amputation hazards often occur when guards are missing or inadequate, equipment is poorly maintained, or hazardous energy isn’t controlled during servicing/maintenance activities.

The NEP covers 91 six-digit NAICS codes where OSHA has identified elevated risks of machine-related amputation injuries. These industries include a broad range of manufacturing sectors that use machinery with exposed moving parts, presses, conveyors, and equipment requiring lockout/tagout procedures. Some of the covered industry sectors include:

- Food and Beverage Manufacturing

- Wood and Wood Products

- Paper and Packaging

- Plastics and Rubber Products

- Primary Metals and Metal Products

- Machinery and Equipment Manufacturing

- Furniture and Miscellaneous Manufacturing

General Takeaways on NEPs

It’s important to understand each of the current NEPs and whether your facility might be a target because of them, either because of the nature of risks present or because of your industry sector.

However, there’s another key takeaway. These NEPs are another urgent reason to ensure your injury and illness records are in order. That’s because multiple current NEPs explicitly state that OSHA compliance, safety and health officers (CSHOs) will be reviewing those records during the inspection.

For example, the NEP for warehousing/distribution states that during the opening conference, the CSHO will review OSHA 300 logs, 300A injury and illness summaries, and 301 incident reports for the current year and three previous calendar years to identify recorded injuries and illnesses associated with the focused hazards covered by the NEP.

The NEP also states that when inspecting an establishment that had obligations to electronically submit 300A data to OSHA via the Injury Tracking Application (ITA) but did not submit, CSHOs will follow guidance listed in OSHA’s Interim Enforcement Procedures for Failure to Submit Electronic Illness and Injury Records under 29 CFR 1904.41(a)(1). In short, if your establishment should have electronically submitted injury and illness data to OSHA but did not, you’re at greater risk of increased scrutiny during the inspection and potential violations and fines.

#3: Upcoming and Ongoing Regulatory Changes

While the pace of regulatory change in the U.S. has slowed over the past year, it hasn’t stopped, and EHS professionals need to understand how the most recent changes will impact them. Here are some of the most significant changes you need to keep top of mind.

HazCom 2024 Compliance Timeline

OSHA’s Hazard Communication (HazCom) Standard is one of the most widely applicable safety regulations in the U.S., affecting chemical users throughout the supply chain. That’s why it’s monumental whenever OSHA updates the standard, as they did via a final rule issued in May 2024 which is already in effect.

The final rule introduces significant changes to HazCom. Here are some of the key updates:

Hazard Classifications

HazCom 2024 expands the aerosols hazard class to include non-flammable aerosols, now categorized under a new Category 3. This adjustment aims to enhance user understanding of the specific hazards associated with various aerosols, and the ways that container failure mechanisms differ from those of gases under pressure (gas cylinders), the category that many aerosols previously found themselves in.

The rule also adds a category for chemicals under pressure, following and adopting the categories of chemicals under pressure from GHS Revision 8. The new classification includes liquids or solids pressurized with gas, which improves hazard communication clarity.

Another critical update is the addition of desensitized explosives as a new hazard class. These products, stabilized with a wetting or stabilizing agent, are safer to handle than ordinary explosives as long as the stabilizing agent is in place and effective. The classification system now includes four categories based on corrected burning rates, offering detailed stability and hazard information to users, including how to confirm that stabilizing agents are in place.

The final rule also modifies the classification of flammable gases, splitting Category 1 into subcategories 1A and 1B, better distinguishing hazards associated with different flammable gases. Pyrophoric and chemically unstable gases fall under Category 1A, emphasizing the need for specific hazard and precautionary statements for safe handling.

Labeling Requirement Changes

HazCom 2024 introduces new allowances for small and very small containers. For small containers (up to 100 milliliters), manufacturers can use abbreviated label information if the full shipped container label information is on the outer packaging.

For very small containers (up to 3 milliliters), only the product identifier is required on the container, if the manufacturer argues that a label would interfere with the normal use of the container. Once again, a chemical manufacturer who takes advantage of this allowance would need to provide full shipped container full label information on the outer packaging.

Both manufacturers of small and very small containers also need to include a statement on the outer packaging telling users to replace the small and very small containers in the outer packaging when the containers are not in use.

These allowances and requirements balance the need for hazard communication with practical labeling considerations, ensuring essential safety information remains accessible.

Chemicals Released for Shipment

A significant update to the HazCom Standard relieves chemical manufacturers of the need to relabel “chemicals released for shipment” if they learn of new hazard information. However, they still would need to provide an updated shipped container label with the shipment.

This change reflects OSHA’s consideration of the lengthy distribution cycles for some products, which can lead to extended warehouse storage. Previously, new hazard information required relabeling, posing risks during the process, since employees would need to access containers that may already have been bundled and palletized.

HazCom 2024 Deadlines

OSHA has recently (as of January 15, 2026) updated the deadlines for manufacturers of chemicals affected by the most recent HazCom changes. The new deadline for manufacturers of substances is May 19, 2026, and the new deadline for manufacturers of mixtures is November 19, 2027, which are now four months later than the original deadlines. Employers who have the affected chemicals in their worksites have deadlines six months after those respective deadlines to make sure they’ve received updated SDSs and shipped container labels from their suppliers and are using the information to update their written HazCom plans and workplace containers.

It’s also worth mentioning that the March 1 deadline for Tier II reporting is fast approaching. And a brief side note: The EPA may update Tier II forms to align them with the revised hazard classifications as it did sometime after the last HazCom revision. There’s no known timeline for this change to happen, but at this point, it wouldn’t impact the RY2025 reports due March 1. If forms are updated this year, you may be required to use them for RY2026 reports due by March 1, 2027.

Poly and Perfluoroalkyl Substances (PFAS)

PFAS, known as forever chemicals, are a group of synthetic chemicals that have been widely manufactured since the 1940s. The most well-known and frequently studied PFAS are perfluorooctanoic acid (PFOA) which is used in the manufacture of Teflon, and perfluorooctane sulfonate (PFOS), a common ingredient in fabric protectors and stain repellants.

Additional products containing PFAS, and locations where PFAS contamination have been found include:

- Commercial household products, including polishes, waxes, paints, cleaning products, firefighting foams, nonstick products (including Teflon), such as cookware, and stain and water-repellant fabrics

- Packaging, including packaging for some food products

- Workplaces that commonly use PFAs, including production facilities or industries, such as chrome plating, electronics manufacturing, or oil recovery.

- Drinking water, when locally impacted by specific industries that use PFAS. This is an issue that has understandably attracting a great deal of recent attention.

The presence of PFAS in consumer products and the environment has become a growing concern due to studies demonstrating a link between PFAS exposure and reproductive and developmental defects, liver and kidney damage, immunological effects in laboratory animals, and the development of tumors.

Findings also consistently show increased cholesterol levels among exposed populations. Adding to the concern, PFAS are persistent, bioaccumulative toxic (PBT) chemicals, meaning that they resist degradation and accumulate over time. Due to these concerns, agencies around the world have increasingly passed regulations addressing various facets of PFAS, from reporting on PFAS still in use to remediation of soil and groundwater contaminated with PFAS.

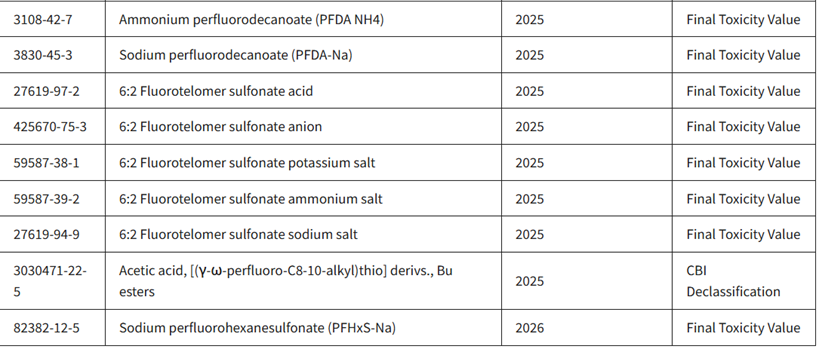

In the United States, one of the major areas of compliance focus regarding PFAS has been the addition of specific PFAS to the list of Toxic Release Inventory Reporting (TRI) chemicals, aka Form R chemicals, via a provision of the National Defense Authorization Act (NDAA). The chart below shows all of the PFAS added to the TRI list for the most recent two reporting cycles.

As the chart shows, there were eight additional PFAS added to the reporting list for reporting year (RY) 2025, which means that if you used these chemicals in 2025, you need to determine if the amounts manufactured, processed or otherwise used exceed the 100 lb. reporting threshold. This is much lower than the usual thresholds of 25,000 lbs. for processed or manufactured chemicals or 10,000 lbs. for “otherwise used” chemicals,” and if so, prepare to report them by the July 1, 2026 Form R deadline.

There was only one additional PFAS added for RY2026, which means you need to determine if you use that chemical (specifically, sodium perfluorohexanesulfonate) now so you can track your usage over the course of 2026 and report it by July 1, 2027, if the usage exceeds 100 lbs.

Keep in mind that there is a separate U.S. reporting requirement on PFAS that began this past year on July 11, 2025. This separate reporting under the authority of the Toxic Substances Control Act (TSCA) requires any person that manufactured (including imported) PFAS or PFAS-containing articles between January 1, 2011 and December 31, 2022 to electronically report information to the EPA.

The required information covers PFAS uses, production volumes, disposal, exposures, and hazards. In November 2025, the EPA announced plans to potentially amend this requirement to reduce administrative burden or duplicative reporting efforts.

While a key focus in this blog is on U.S. regulations concerning PFAS, it’s important to remember that many global agencies are focusing on forever chemicals as well. For example, the EU has added a number of PFAS to the Candidates List of Substances of Very High Concern (SVHCs), a designation that serves as a first step to additional regulatory actions, and which triggers transportation requirements. You can expect more PFAS to be added to that list over time, which means it’s only getting more important to understand whether you have PFAS in your inventory, no matter where you operate.

Indoor and Outdoor Heat Exposure

OSHA has been focusing more on occupational heat exposure in both indoor and outdoor work environments over the last five years or so. Their efforts initially focused on education and outreach, helping workers understand the dangers of heat strokes or other heat related illnesses, and helping employers understand that protecting employees from severe heat risks is part of their obligation under the General Duty Clause of the Occupational Safety and Health Act.

However, OSHA began gathering information for a potential rulemaking several years ago, and in August 2024, the agency issued a notice of proposed rulemaking (NPRM) called Heat Injury and Illness Prevention in Outdoor and Indoor Work Settings.

Key provisions of the NPRM include:

- Employers would need to develop a Heat Injury and Illness Prevention Plan (HIIPP) and make it site-specific to their worksites.

- Proposed requirements for monitoring of heat conditions, including defined heat triggers (e.g., heat index thresholds).

- Preventive measures based on heat levels, including providing cool drinking water, shaded/cool break areas, rest breaks, acclimatization procedures, and training.

- Additional protections when temperatures reach higher heat triggers (e.g., mandatory rest periods and active observation for heat illness signs)

While the public comment period for the NPRM closed in early 2025, OSHA held an additional, extended stakeholder meeting from June 16 to July 2, 2025 to address the feedback it received and solicited additional input to help develop a final rule.

Once OSHA published a final rule in the Federal Register, the compliance timeline will officially start for the rule to go into effect. It’s hard to say how long that may take, but it’s possible the rule will come in 2026. Until then, OSHA will continue their renewed focus on heat exposure via the General Duty Clause, and the heat NEP currently in effect.

Stay tuned during 2026 for updates on the occupational heat exposure final rule, or other OSHA initiatives to prevent heat related illnesses.

#4: Recordkeeping for Injury and Illness

Injury and illness recordkeeping is important because it’s sometimes a regulatory requirement, such as under OSHA’s Recordkeeping Standard in the U.S., which requires covered employers to maintain Form 300 (Log of Work-Related Injuries and Illnesses). Form 301 (Injury and Illness Report, completed for each individual recordable incident), and Form 300A (Summary of Work-Related Injuries and Illnesses).

It’s even more urgent to understand Recordkeeping because of recent changes to the electronic injury and illness reporting requirements under the Standard. In a recent blog, 2025 Is Almost Over—Are Your OSHA Logs In Order?, we highlighted OSHA’s 2023 electronic reporting final rule, which went into effect in January 2024, updating requirements since initially established via a 2016 final rule.

At a very high level, the 2023 OSHA final rule created four different categories of electronic reporting obligations, depending on establishment size and industry sector, as shown in the chart below.

| Establishment size (# of employees) | Industry sector | Electronic injury and illness reporting requirements |

| <20 | All industries | No electronic reporting requirements |

| 20-249 | Listed in Appendix A of 29 CFR 1904 | Electronic 300A reporting |

| 100+ | Listed in Appendix B of 29 CFR 1904 | Electronic 300, 300A and 301 reporting |

| 250+ | All industries covered by the Recordkeeping Standard | Electronic 300A reporting |

It is still early in the lifetime of the updated requirements, with RY2025 submissions due March 2 to OSHA via the Injury Tracking Application, representing just the second reporting cycle. Some organizations aren’t aware that the changes are in effect and have not yet determined their electronic reporting applicability under the updated requirements. As mentioned in the discussion of NEPs, OSHA is targeting establishments that should have reported, but did not, so make sure you’re on the right side of compliance.

It’s also important to remember the purpose of recordkeeping is to ensure that you have details about workplace injuries and illnesses to prevent injuries, which is the next trend to review.

#5: Preventing Severe Injuries and Fatalities (SIFs)

OSHA has always prioritized its regulatory and enforcement actions based on prevention of SIFs, and with downsizing of OSHA under the current U.S. federal administration, this is truer than ever.

In 2026, EHS professionals should rededicate themselves to the primary goal of all EHS management—protecting the health and safety of the workforce and preventing the most serious injuries. Those leading to hospitalizations, long-term changes in health, or worse, death.

Look at the chart below, showing trends in injuries and fatal injuries from 2002 to 2022.

The trends here are telling. The normalized rates for serious incidents—including fatalities, which are the worst possible outcome, increased more than the rates for less serious incidents in recent years.

Additionally, the chart shows that the fatal injury rate has remained extremely consistent between 2002 and 2022. There’s been more success in reducing the rates and numbers of less severe incidents than there has been in reducing fatality numbers. That’s not the expected outcome if we were doing well at assessing risks and addressing them before serious incidents could happen.

It’s not that EHS professionals aren’t trying to proactively address risks. The issues are gaps in information and inability to leverage data for insights about potential SIF (PSIF) risks.

Gaps in information could include incomplete incident descriptions, which make it less likely that you’ll have the information you need to understand what happened, or common mistakes or unintentional shortcuts in root cause analysis (RCA), in which you try to identify the underlying, systemic reasons why an injury or illness occurred. For example, many EHS professionals haven’t received training on how to think through a process beyond citing human error. If they use software for RCA, the software may present them with too many choices or too little guidance for selection.

Harvesting usable information on PSIFs is also a significant challenge. The received wisdom in EHS management is that targeting general reductions in injuries will move the needle on reducing SIFs, but that turns out not to be true. Only 20% or less of all incidents have the potential to cause a SIF, so the difficulty is identifying that subset of risks that may be lurking in the details of less serious incidents, like near misses.

Luckily, modern incident management software with AI capabilities can help by assessing incident descriptions and offering improvement suggestions, or presenting curated RCA choices based on machine learning trained on real EHS datasets by real EHS professionals. That same embedded expertise can also help identify that subclass of PSIF risks, so you can focus your efforts where they will have maximum impact.

Key Takeaways for EHS Professionals

Let’s conclude this discussion with a few key takeaways.

Know Your Chemical Inventory

Whether you’re looking to improve compliance with updated HazCom requirements or seeking insights into PSIF chemicals, you need better visibility of your inventory at the ingredient level.

Improve Your Injury and Illness Recordkeeping

Injury and illness records not only help you maintain compliance with requirements from the Recordkeeping Standard, but also help you prepare for possible inspections, including under existing OSHA NEPs. More importantly, they’re the foundation of a proactive safety management approach.

Focus on Identifying and Addressing PSIFs

Speaking of being proactive, there’s nothing more beneficial to workplace safety than preventing SIFs. Identify the tools you need to find those PSIF risks within the details of less serious incidents, such as near hits/near misses/close calls.

Start On Your Journey to a Smarter, Safer 2026

VelocityEHS has resources to help you master chemical management, like our popular HazCom webinar, the compliance checklist and FAQ on the 2024 final rule.

Do you need to conduct Tier II reporting, or need to ensure you’re meeting your obligations? You can attend our upcoming Tier II webinar, and in the meantime, download our Tier II cheat sheet and Tier II guide. If you’re looking for guidance on TRI/Form R reporting, we have an on-demand webinar you’ll enjoy watching. And if you’re still trying to better understand PFAS and your potential obligations around them, download our handy infographic.

If you’re looking to finally start improving your tracking and control of PSIF risks, check out our on-demand webinar. Finally, visit our AI resource center to learn how AI-enhanced EHS software can give you the support you need to sharpen your management practices in 2026 and beyond, or download our white paper “Why EHS Professionals Can’t Afford to Ignore AI.”

Let’s make workplaces safer, together

Start your new year off with award-winning EHS software from VelocityEHS that empowers you to stay ahead of risk.

Leverage key capabilities, including AI PSIF Insights and AI-enabled enhancements to improve root cause analysis, strengthen incident descriptions and support better corrective action selections. Machine-language powered chemical ingredient indexing, available as a service, gives you sharper insights into high-risk, high regulatory burden chemicals in your inventory.

Learn more about capabilities like these and the entire suite of VelocityEHS solutions to see how you can level up safety performance. Get in touch today to set up a meeting, so you can outpace risk in 2026.